Join us at the International Thermal Conductivity Conference (ITCC) and the International Thermal Expansion Symposium (ITES).

Geological

Nanomaterials

Pastes

Pastes

Polymers

Other techniques used to measure the thermophysical properties of polymer melts were dangerous, messy, and risked damaging the sensor. However, the MP-1 TPS Polymer Melt Cell holder, designed by Thermtest Inc., makes it possible to safely and accurately measure thermophysical properties, for instance, the thermal conductivity of polymers, from the solid state, through a melt, and into the liquid state.

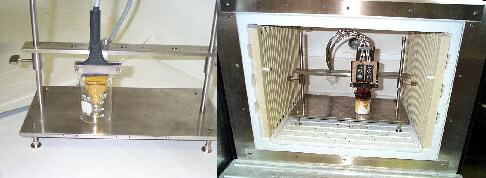

In the past, measuring the thermophysical properties of plastics was rather difficult. This was mainly due to the phase transition, and therefore sample melting, at high temperatures. Historically, the transient line source technique was used to determine the thermal properties of molten polymers, until the TPS method was adjusted to perform measurements on polymer pellets. This new technique inserted the sensor vertically into a container filled with polymer pellets, rather than horizontally, as shown in Figure 1.

This method is less than ideal, as the TPS sensor cannot be easily removed from the re-solidified sample, without potentially being damaged. As a result, researchers here at Thermtest have been actively working to produce an effective method to test the thermal conductivity of a polymer through its melt. The newly developed polymer melt cell, to be used in conjunction with the TPS system, can safely and accurately measure the thermal properties of polymers through a melt. The use of this melt cell allows for an easy cleanup and does not risk damaging the sensor.

Figure 1. Past setup for testing the thermal conductivity of plastic. 1

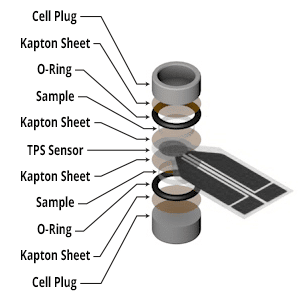

As previously introduced, the design of the polymer melt cell focuses on containing polymer samples through a melt. To do this, various types of o-rings with an outer diameter of 25.3 mm, and thickness of 3.2 mm, surrounds the material in the sample holder to keep it in place. Numerous tests were conducted to determine the perfect O-ring material.

To separate the molten polymer sample from the melt cell and the sensor, various types of insulation with the same diameter as the O-ring is placed on each side of the O-ring/polymer sample combination. Moreover, as the polymer melts, the insulation layers form a seal with the O-ring, inevitably forming a puck-like structure.

Firstly, the polymer samples must be mechanically cut into identical circular pieces, 18.6 mm in diameter, and 3.2 to 2.8 mm thick. Before loading the polymer sample into the lower half of the melt cell, a thin piece of insulation is laid on the bottom plug of the cell (Figure 2). Following this step, the O-ring is placed on top of the insulation, and the polymer sample is snapped into place within the O-ring.

Next, another thin layer of insulation is placed on top of the sample. Likewise, these steps are to be repeated for the sample in the upper half of the melt cell. Additionally, a coat of Boron Nitride is applied to the inner portions of the melt cells to allow for easy clean up, if by chance the sample reacts with the hardened steel.

Figure 2. Layering in the polymer melt cell.

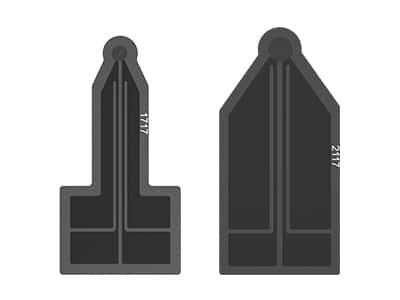

At this instant, the sensor must be placed between the two sample holder halves. Two sensors may be used in conjunction with the melt cell: the 3.2 mm radius, or the 2 mm radius (Figure 3). Although, the 3.2 mm radius is best used with anisotropic samples, as its larger size allows for more representative thermal conductivity results, the 2 mm radius is smaller and is best used with isotropic samples. Once the sensor is centered on the sample, the upper and lower melt cells are fastened together.

Figure 3. 3.2 mm and the 2 mm radius. 3.2 mm diameter sensor and 2 mm diameter, respectively.

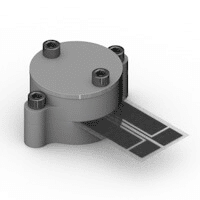

Once both samples and the sensor are in place, a plug is set into the upper melt cell, on top of the polymer sample an insulation, and springs are placed within the plug to compress the samples tightly against the sensor. Notably, three springs, of various sizes, are supplied with the polymer melt cell sample holder.

Although, researchers at Thermtest have found that the best results are obtained when the two largest springs are used together. Thus, applying approximately 82 pounds of force onto the sample. To complete the set-up, a metal plate is screwed to the top of the upper melt cell to compress the springs (Figure 4).

Figure 4. Closed polymer melt cell ready for testing.

Prior to conducting measurements, the sample holder is placed inside an MP-1 TPS Temperature Platform (TP) or TPS oven are able to measure up to 300 °C. The temperature platform is a fast convenient option for testing one sample, while the oven can be configured up to four samples for higher volume applications, which used with the TPS Expansion Switch.

Furthermore, once the samples have gone through the melt stage, an imprint of the sensor is left on the polymer puck (Figure 5) to prove that contact was maintained throughout the phase changes.

Figure 5. An imprint of the TPS sensor left on the polymer puck.

Below, results from tests conducted on polycarbonate and acrylonitrile butadiene styrene (ABS) in the Thermtest lab, using the polymer melt cell, are outlined. Accordingly, measurements were performed from room temperature to approximately 300°C, in the previously mentioned TPS Standard Oven 1.

Five replicate measurements were performed to establish repeatability. Additionally, the relative standard deviation (RSD), the amount of deviation between a set of measurements, was calculated. With this in mind, results are considered repeatable if RSD is less than 2%.

The relative difference (RD) compares experimental values with known literature values, and in this case, a difference of less than 5% is optimal. Unfortunately, RD was only calculated for the ambient measurements, as literature values for each temperature interval were not available.

Table 1. Heating powers (W) and test times (s) for polycarbonate and ABS samples that were tested in the polymer melt cell.

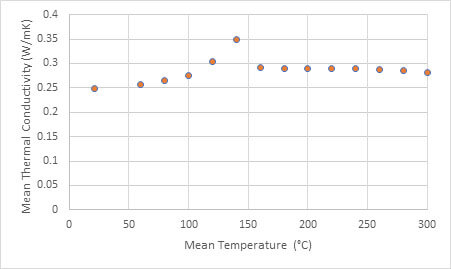

In the final analysis, the results were well within the acceptable range of repeatability, and accuracy (Figure 6). Correspondingly, the literature thermal conductivity value of polycarbonate at room temperature was 0.25 W/mK, and the experimental value was 0.2564 W/mK, an RD of 2.5%, well below the stated accuracy.

Figure 6. Mean thermal conductivity of polycarbonate tested in the polymer melt cell from room temperature to 300 °C.

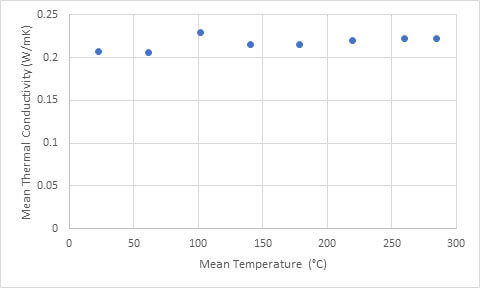

In like manner, ABS showed good repeatability between tests, and a high accuracy, as the measured value was within 0.8% of the literature value (Figure 7).

Figure 7. Mean thermal conductivity of ABS tested in the polymer melt cell from room temperature to 300 °C.

Thermtest is proud to announce the completion of our newly developed polymer melt cell that will revolutionize thermal property measurements of polymer melts. Coupled with the MP-1 transient plane source system (TPS), the polymer melt cell allows users to easily collect accurate thermal property measurements throughout a melt.

The most attractive feature of the polymer melt cell, is its ability to neatly contain the polymer sample in a puck form, so that no clean-up is required, and there is no damage to the sensor. With its straightforward setup and reliable measurements, Thermtest’s polymer melt cell sample holder is a necessity for any thermal conductivity laboratory.

For more information about the thermal conductivity of polymers, please visit the applications page.