Join us at the International Thermal Conductivity Conference (ITCC) and the International Thermal Expansion Symposium (ITES).

Geological

Nanomaterials

Pastes

Pastes

Polymers

During the early-20th century, wearing fur was considered a popular fashion statement among the upper-class. As the mid-20th century approached, people from all classes were indulging in this not-so-trendy fad, as more affordable furs were becoming popular. Because of a relatively low cost, rabbits are and were one of the largest proportions of animals captured for the production of fur. With the arrival of the 1980s and the introduction of the Animal Rights Movements and People for the Ethical Treatment of Animals (PETA), society began to shun and disband the use of fur in the fashion industry. As the world’s clothing industry began to shy away from the fur trade, more efforts and resources were being implemented to discover new fabrics and textiles with similar thermal properties as fur. The low thermal conductivity of fur allows for an increased insulation from the cold: a well-desired trait in frigid, harsh environments. Currently, cruelty-free fabrics, vegan clothing and faux furs have been booming in the fashion market.

Figure 1. Animal fur was once considered to be a sign of wealth.1

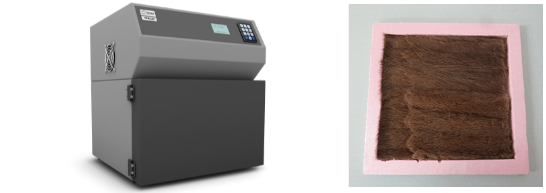

Using the Thermtest Heat Flow Meter (HFM), the bulk thermal conductivity (W/m·K) of a sample of fur was measured at upper and lower temperatures of 25°C and 15°C, respectively. The HFM is a state of the art instrument which establishes a steady-state heat transfer system to measure the thermal conductivity and thermal resistivity of flat slab insulating materials such as foams, solids and textiles. The HFM measures thermal conductivity over a range of 0.005 to 0.5 W/m·K and over a temperature range of -20°C to 70°C, in accordance with ASTM C518-15 – Standard Test Method for Steady-State Thermal Transfer Properties by Means of the Heat Flow Meter Apparatus. Having the correct sample thickness is key. Therefore, prior to placing the fur sample in the HFM to be tested, a foam quadrant was constructed around the sample. As the test was conducted, the foam quadrant received the brunt of the parallel plates compression force and assured the fur was in its most natural state.

Figure 2. Thermtest Heat Flow Meter displayed on the left and the fur sample, encased in the foam quadrant (pink) displayed on the right.

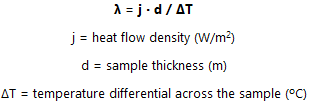

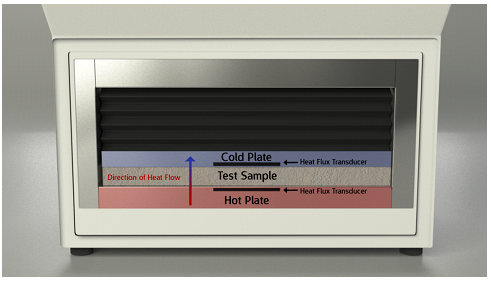

To begin each test, a desired specimen is placed between two parallel plates within the HFM. A user specified temperature gradient across the plates is established and the upper plate is set to compress onto the specimen to the desired sample thickness. At constant, but distinct temperatures, the HFM parallel plates establish a steady state, one-dimensional heat flux through the test specimen. Thermocouples are embedded in the plates to measure the temperature on either side of the sample specimen. The heat flux transducers, in contact with the upper and lower plates, collect data on the resulting heat flux of the test specimen. By appropriate calibration of the heat flux transducer(s) with standards, and by measuring the plate temperatures and plate separation, Fourier’s law of heat conduction is used to calculate thermal conductivity (λ):

Figure 3. View of the inside of the HFM door. Parallel plates (red and blue) establish a one dimensional heat flux (arrow) through the test specimen, simulating heat loss from the body to the cold external environment.

To simulate environmental conditions, the fur was tested to mimic heat loss from a warm body to a colder external environment. The fur tested displayed a thermal conductivity reading of 0.0357 W/m·K, similar to the readings received by both Cena and Clark (1978), and Hes (2004). According to Cena and Clark (1978), artificial fur (40 – 67 mW/m⸳K) has the same, if not lower thermal conductivity readings than rabbit fur (38 – 100 mW/m⸳K). These results point towards the sustainable and animal-friendly use of artificial furs in clothing products, over the traditional animal furs. As means to completely deter the use of furs in the fashion industry, more studies to discover other artificial fabrics, with similar thermal properties to fur, is needed.

Disclaimer: No animals were sought after or harmed for the purpose of this research.

The Thermtest Heat Flow Meter (HFM) provides users with the ability to measure thermal properties of larger, flat slab specimens ranging in thermal conductivities from 0.005 to 0.5 W/m∙K. The Heat Flow Meter is capable of measuring the steady-state heat transfer properties of foams, solids, and textiles.

References:

Image Source: